Estimating 6′ Floating Shelves with Sheppard Brackets’ Options.

When you need something built, finding the right contractor is tough. Pictures and reviews only tell you so much about knowledge and skill. What really separates a carpenter is their ability to listen, adjust and write detailed estimates. People don’t usually consider this when it comes to cost. But it’s worth it. I can prove it to you by running through my process when estimating 6′ shelves last month.

Introducing the Wood Project.

Here in Memphis, I get quite a few random requests. Most people make decisions based on price alone. But this can be tricky. Paying an expert to help you make the best decision is valuable, no?

When I was asked to build custom shelving for an interior designer in Germantown, TN – I knew the process would be appreciated. Initially, the client was looking for rough, 1 1/2″ thick wood for some 18″ by 6′ floating shelves. However, she knew it was going to be a challenge.

The Work That Goes into Estimating.

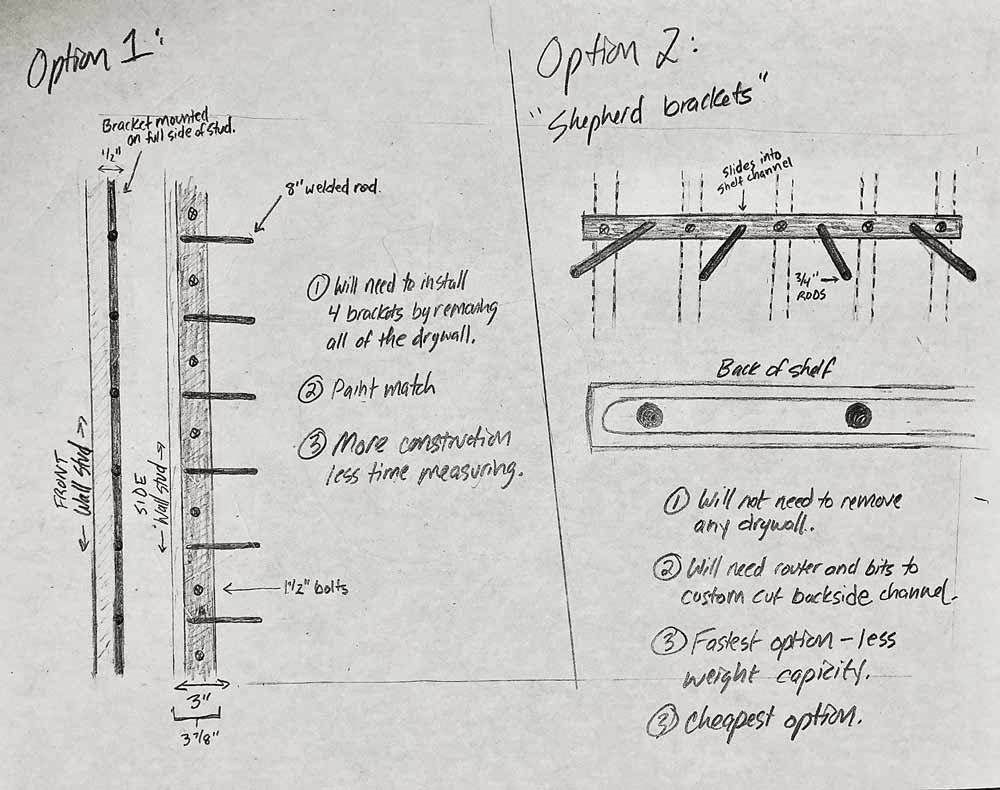

After stopping by the house to see the wall, a ton of ideas ran through my head. I presented the client with some wood options with costs and began formulating ideas to float the shelves. But the more I thought about the dimensions, the more I realized they probably weren’t going to work.

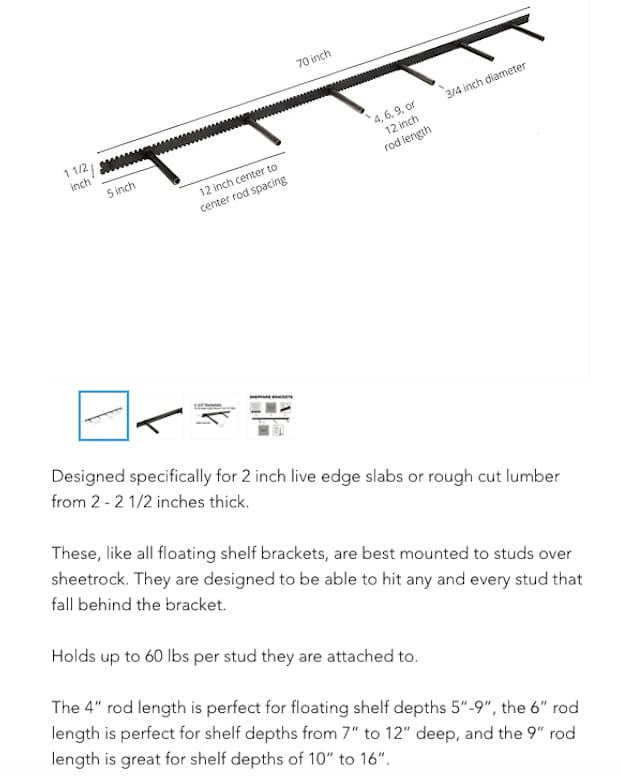

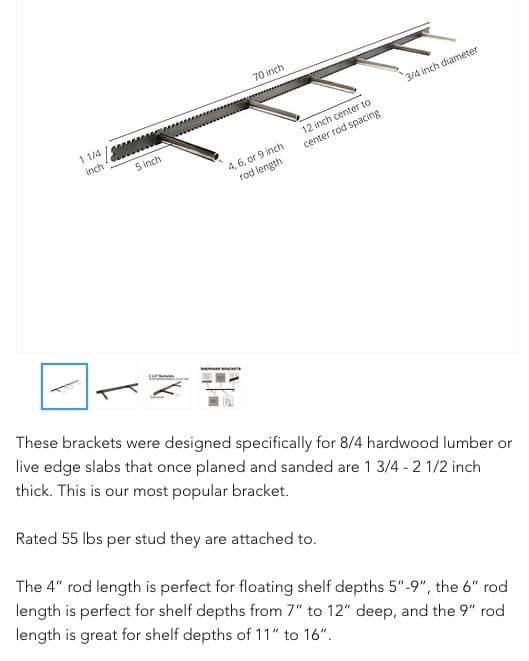

I even designed my own brackets with threaded rods. But I wasn’t confident in the strength of a floating board that thin. Wood like cedar just wasn’t coarse enough. After stopping by Home Depot to browse and City Wood to see how they float their slabs, I decided we needed to head towards 2″. Thankfully, the client agreed.

6' Floating Shelves Don't Cost $500.

At this point, a lot of time was invested in the project. I hadn’t even plugged in a saw yet. My point is, home service is more than just labor. Custom work is a process.

From here, we went back and forth on material for about a week before deciding that an 18″ width was too much. My client made a few calls and found some gnarly 6′ reclaimed boards from Jason at Southend Reclaimed. It was less money than other options – but it didn’t lower the overall price.

The boards were only 10″ wide and I was going to have to adhere them together. It would be another challenge since none of the wood was flush. But the client was informed and confident.

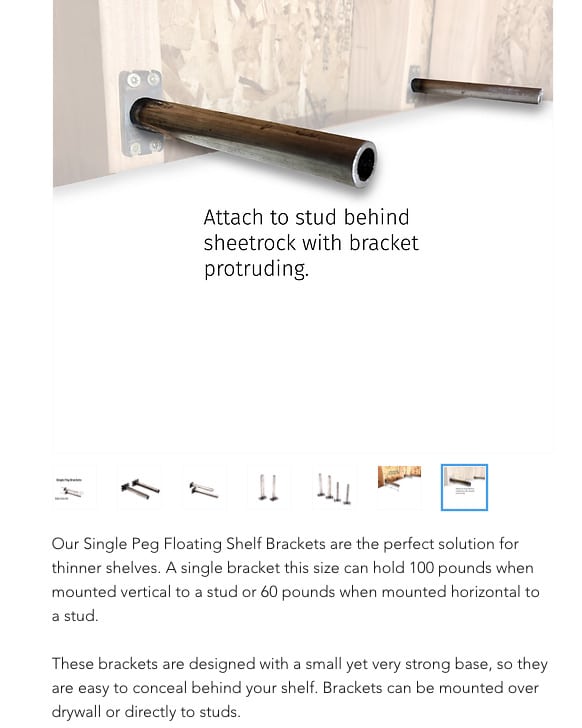

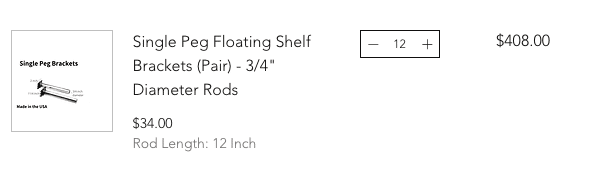

Once the boards were ready, we were finally able to focus on mounting the 6′ floating shelves. The client didn’t want to tear up the wall so I provided her with some options from Sheppard Brackets. Here’s how it went down:

OPTION A:

Cheapest but Strong with More Labor.

Benefits/Details:

- 400 lb limit (no side tabs).

- 12” pegs for <18” depth.

- Fairly cheap product cost.

- Won’t have to remove drywall.

- Will need paint match.

- Drill bit/hole guide $80.

- More skill to align drill holes.

- A little more labor (12-15 hrs).

Product + Install Estimate: $XXXX.XX

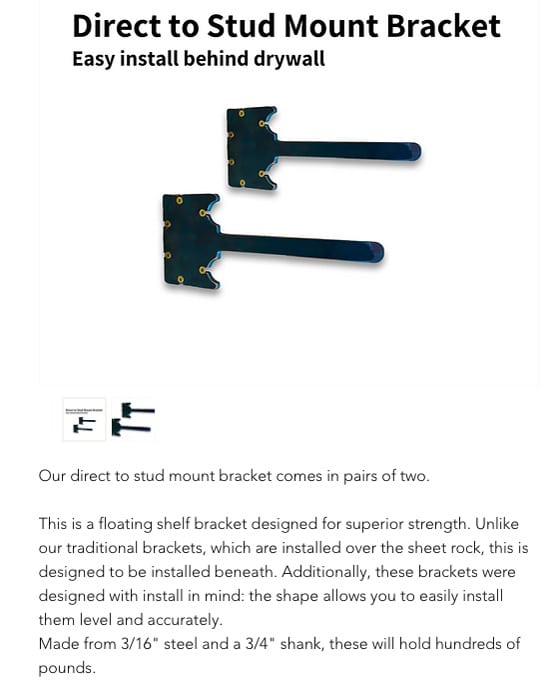

OPTION B:

Strongest & Decent Price with Most Labor.

OPTION C:

Sturdy but Pricey with Minimal Labor.

OPTION D:

Less Sturdy but Pricey with Minimal Labor.

Do You Value Custom Work?

Every step of the project made it difficult to estimate the cost of a 6′ floating shelf. Despite the curveballs (and more to come, I’m sure), we’re still pretty close to the original proposal. When your effort is valued, the job is a lot more gratifying.

Now you know why handy Randy charges a lot more. He just cares. That’s all.